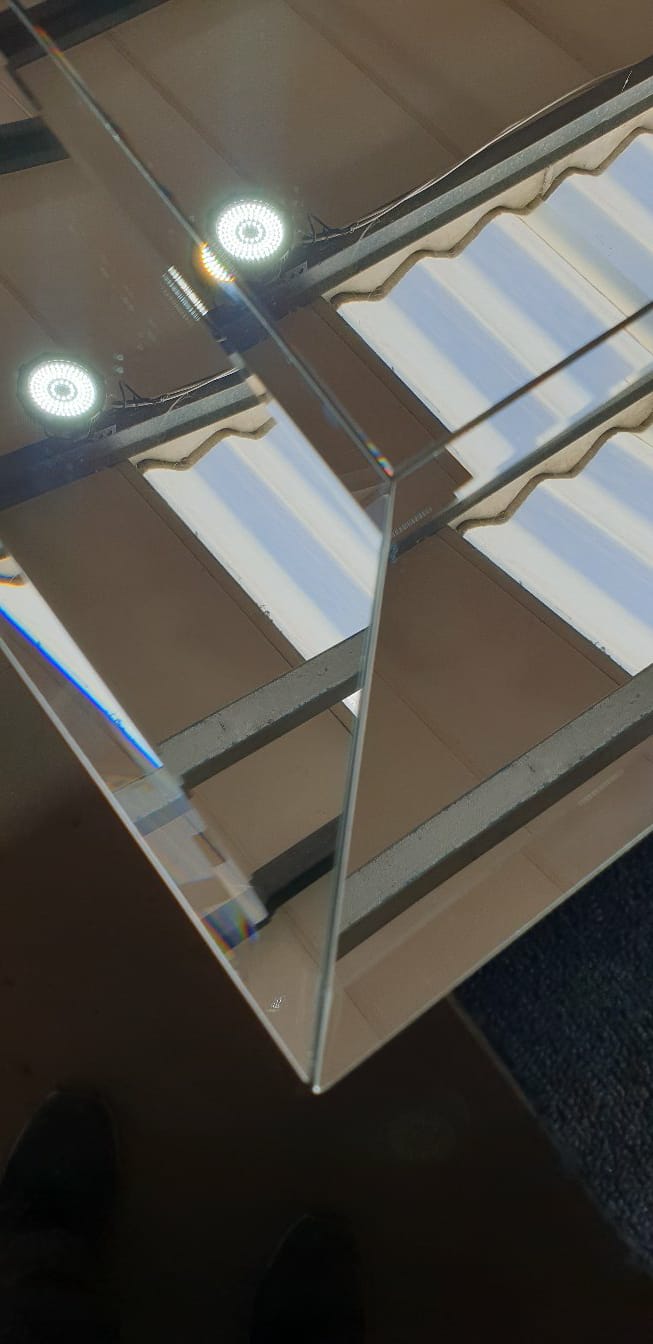

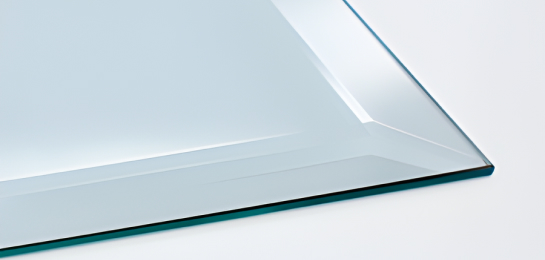

Circular bevelling is a glass and mirror finishing technique that involves creating a chamfered, smooth edge on the periphery of the glass or mirror surface. The circular bevelling process is achieved by using a specialized grinding wheels with diamonds on a circular beveller, worked by one of our employees who have years worth of experience. This technique not only enhances the aesthetic appearance of the glass or mirror but also adds a touch of elegance and safety by eliminating the potential for sharp corners or edges. Circular bevelling is commonly used in various applications, including furniture, decorative mirrors, and tabletops where a seamless and bevelled finish is desired.

Juno Mirrors and Glass is the leading bevelling company and circular bevelling company in London, with two straight edge bevelling machines and two specialist circular bevellers.

For the polishing service, we are talking about polished edges. A polished edge has been machine polished smooth so we can get rid of the rough edges of the glass. As a result, this gives it a clean sharp finish. This would be suitable for display purposes, such as mirrors, retail display cases and other decorative furniture.

In regards to glass drilling, we refer to cutouts. Many frameless glass hardware applications require holes notches and cut-outs to be included into the final design. We are able to add a bespoke cut out in any shape that is required for your particular appliance and situation. In certain circumstances, glass with holes, notches, and cut-outs will need to be toughened for safety purposes.

Interested in something unique?

If you’re searching for a customisable project, visit our quote builders to kick-start your project!